Honeycomb shape plastic support block is made of synthetic plastic injection molding. The formula can be adjusted according

to different working conditions to achieve the best effect. It completely replaces the light ceramic packing commonly used

before. The honeycomb shape plastic support block developed by us can be used repeatedly, with large specific surface area

and large ventilation capacity, and its effectiveness is twice that of light porcelain. Especially in the process of maintenance, the

light ceramic packig becomes solid waste, which is difficult to deal with. But honeycomb shape plastic support block can be

reused as renewable resources, which is environmental protection and energy saving. Through the long-term test of Coking

Desulfurization Tower. It is proved that honeycomb shape plastic support block has strong anti blocking ability and excellent

separation and purification effect.

Size :

248mmMaterial :

FRPHAdvantage of Honeycomb shape plastic support block

1.Developed by us, can be used repeatedly, with large specific surface area and large ventilation capacity and its effectiveness is twice that of light porcelain.

2.honeycomb shape plastic support block can be reused as renewable resources, which is environmental protection and energy saving.

3.The product has a long service life and large operation flexibility

Product Detailed Pictures

|

|

Technical Data

| size mm | surface area m2/m3 | void fraction % | bulk number pieces/m3 | bulk density kg/m3 | pressure ddrop pa/m |

| 248*238*100 | 145 | 95 | 210 | 100 | 20 |

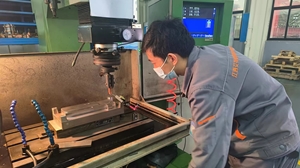

Prodution Process

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application:

1. It is widely used in petroleum, coking, power generation, chemical fertilizer, synthetic ammonia and other coal chemical and fine chemical industries.

2.It is used as filler in the chemical process of gas purification such as desulfurization, washing, debenzylation, dealkylation, ammonia distillation, refining, absorption, drying and synthesis.